Powder Coating Machine

Warranty :

1yearItem No :

THD601Order(MOQ) :

2Payment :

T/T,L/C,Western Union,Paypal and credit card.Product Origin :

ChinaLead Time :

NegotiableManual Electrostatic Powder Coating Machine

Description

This spraying machine THD601 is a strip display light with high powder utilization rate, which can reach more than 95%. The coating film is thin and even, smooth and without sagging.Electrostatic spraying utilizes the principle of static electricity to evenly deposit powder onto the surface of workpieces, enhancing the uniformity and quality of the coating.

Specifications

Model:THD601

Power Voltage: 110V/220V

Input Power: 50W

Maximum Output Current: 200uA

Output Power Voltage: 0-100kv

Powder Hopper Volume: 45 L

Item Dimension: 47*44*62cm

Weight: 25KG

Product Images

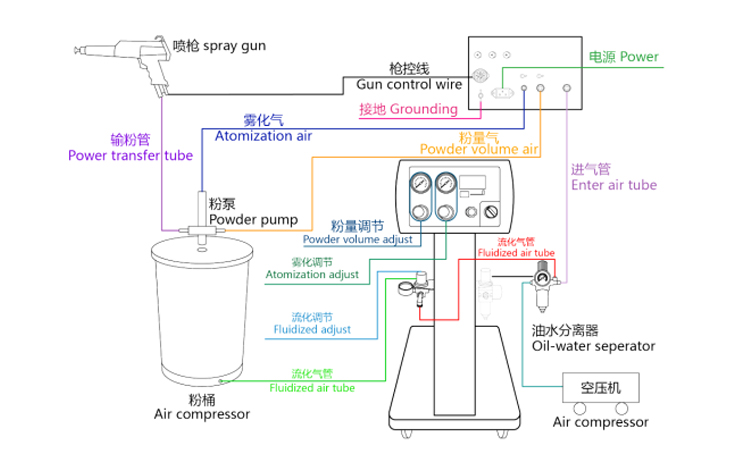

Assembly Diagram

Advantages

High Efficiency Powder Coating System

Simple Control Pane

Excellent Quality

Considerate Details

Commissioning and Usage

1.After long transportation, the machine might bear strong shock, so before using the machine, must check machine structure is fasten or not, all parts are still there, according to the assembly drawing in operation manual, to connect the whole machine, then check the power supply meets the requirement of the machine or not, check the special ground wire is correct or not, then can power on for commissioning.

2.Commissioning method: connect power supply plug, ground connecting well, open the machine power switch, power supply light up, then press gun trigger switch, then twist high voltage adjustment button at clockwise direction. If voltage increase, it means high voltage electrostatic is generated, machine starts working.

3.Usage method: Add powder into hopper, less than 2/3 is the best. Then adjust hopper fluidized air volume, make the powder inside hopper fluidized and loose, then take the gun by hand, press gun trigger switch, then take out and twist powder volume adjusting 2-4 air volume, atomized adjusting switch 0.01-0.25 air volume, adjust to the requested powder volume, then come into service.

4.First time press gun can’t point to work piece, to avoid powder accumulation, should spray until powder spray well, distance to work piece should be 100-200mm.

After using up the machine, pls turn off the power and air source, should clean accumulation powder in the machine, and between powder pump and gun, to prevent room temperature is too high, then cause curing and lead to jam.

Factory Add: Building 25, Kunhuang Industrial Park, Comprehensive Bonded Zone, Luohuang Town, Jiangjin District, Chongqing City

Office Add: Room 8-10, Building 8, No. 48, Danzishi Tenglong Avenue, Tushan Town, Nan'an District, Chongqing

Copyright © 2024 Chongqing Haodong Technology Co., LTD All Rights Reserved.

Sitemap

| Blog

| Xml

| Privacy Policy

Network Supported

Network Supported