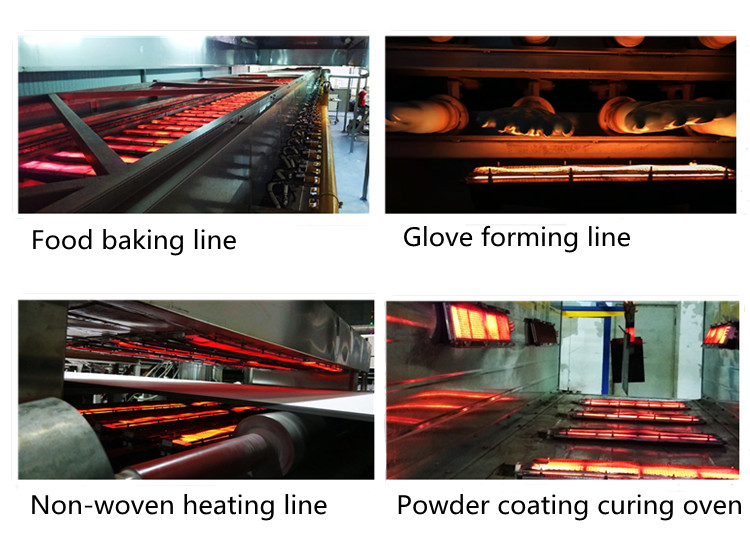

Application Area of Infrared Catalytic Gas Burner

Cast iron body gas burner temperature area is 10- 500℃, it belongs to the low & normal temperature heating. It can work above 8 hours on and on!

Application

1. Surface Treatment Type

a) Electrostatic coating and electrophoresis heating, usually at the temperature range - -250℃;

b) The heating surface lacquer process, usually the temperature range is 180℃;

c) Dip plastic craft heating process, usually at the temperature range -- 400℃;

d) PPGI (prepainted galvanized) coating heating, usually at the temperature range—500℃

2. Food Baking Type

usually the Infrared Gas Pizza Heater Baking heating temperature range is 220~260℃, such as pizza, bread, snow rice cakes, egg roll, biscuits, eels, coffee beans and so on food roasting.

3. Water-removing & Drying

The water-removing processing temperature of tea and tobacco etc usually is 180℃.

4. Fruit & Vegetable Dehydration

Vegetables and fruits dehydration process temperature is 180℃.

5. Glass Annealing

Glass product anneal process temperature is usually 500℃.

6. Latex Thermal Forming Heating

Latex products (such as medical latex gloves) forming heating process is usually 180℃

7. Greenhouse, Farm heating

Infrared gas heater is the best choice for greenhouse, poultry farm breeding, workshops and other sport hall etc. in winter.

8. Clothes Dryer

Clothing drying of large laundry also can use this infrared catalytic burner to heating.

Customer Type

1. End User

a) Powder Coating Industry: colour section aluminum factory, security door factory, steel furniture factory, motor vehicle component factory, electrical equipment cabinet factory and so on;

b) Food industry: biscuit factory, egg roll factory, cake shop & bakery, restaurant & hotels, dried fruit & nut factory etc.

2. Intermediary Business

Powder coating equipment factory, oven manufacturer, food machine factory, paint booth design project company, turn-key project company

BBQ Stretching Body Series

It’s mainly used in BBQ grill, domestic food baking oven, bread deck oven, cooker, roaster, shawarma machine, doner & kebab machine.

This kind of burner is usually under 4 hours’ continuous work.

Application Case for Cost Comparison

A powder coating curing line

Oven size: 30m(L) x 1m(W) x 1.5m(H)

Oven heat preservation temperature: 200℃.

Before it heated by electric tube:

Power consumption: 180KW/h,

Cost of electric: 180kw/h x Local electric unite price = A.

Now use gas burner (LPG):

Installed 20pcs HD242

Burner heat output: 9.4KW/h*20=188KW/h

LPG consumption: 0.67Kg/h*20=13.4Kg/h

LPG cost: 13.4Kg/h x Local LPG unit price = B

(Actually LPG gas consumption is less than B, as the temperature control way.

When the temperature rise to 200℃, the gas will be cut off by the solenoid valve and burner stop working; While the temperature below 200℃, the burner will restart to work.

It means during heat preservation condition there is no gas consumed)

B-A=C, C is the saving cost in an hour.

Notice:

1. When choose the infrared burner model, you must know the oven inner size.

2. The intake-tube can’t be installed in the oven, it must be bared in the air.

3. One set of standard configuration for industrial oven = 1pc infrared catalytic burner + 1pc ignition needle + 1pc electric pulse ignition + 1pc solenoid valve.

Factory Add: Building 25, Kunhuang Industrial Park, Comprehensive Bonded Zone, Luohuang Town, Jiangjin District, Chongqing City

Office Add: Room 8-10, Building 8, No. 48, Danzishi Tenglong Avenue, Tushan Town, Nan'an District, Chongqing

Copyright © 2024 Chongqing Haodong Technology Co., LTD All Rights Reserved.

Sitemap

| Blog

| Xml

| Privacy Policy

Network Supported

Network Supported